How to Lower Thermal Bridging in Your Walls

For designers, architects and engineers, ensuring a home's energy efficiency and occupant comfort involves careful consideration of thermal bridging—a critical but often overlooked aspect of building design. With recent updates to New Zealand's H1 insulation regulations, the significance of accurately addressing thermal bridging has increased dramatically.

Understanding Thermal Bridging

Thermal bridging occurs when heat escapes through building materials with higher thermal conductivity, like timber studs or metal fasteners, creating a pathway of heat loss through the insulated envelope. Despite its critical impact, traditional H1 compliance calculations have historically undervalued the effects of thermal bridging, resulting in buildings that perform below expectations in real-world conditions.

Why Thermal Bridging is Critical for H1 Compliance

Recent changes to H1 insulation requirements emphasize accurate, detailed insulation performance. Designers and engineers must now consider thermal bridging explicitly in their calculations. Ignoring this can lead to:

-

Non-compliance with H1 insulation standards

-

Increased energy use and higher heating costs

-

Condensation and mould issues, leading to poor indoor air quality and structural damage

-

Reduced occupant comfort

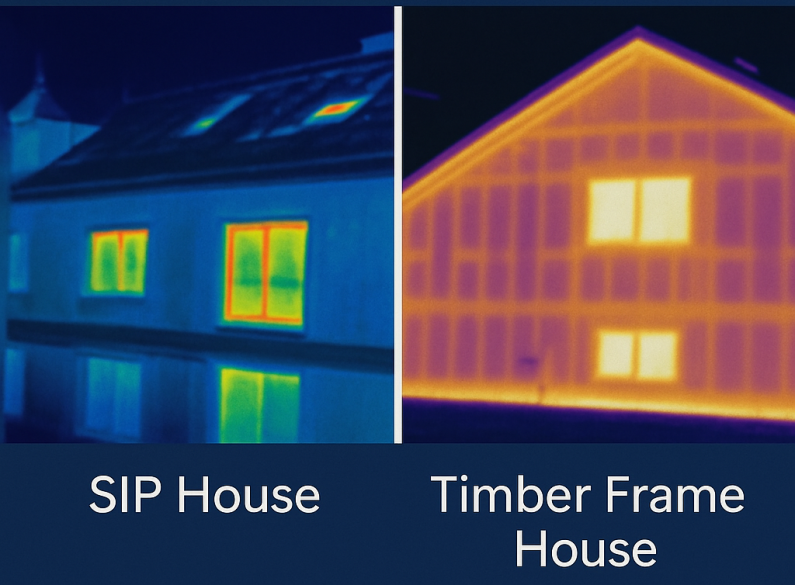

SIPs: A Comprehensive Solution for Thermal Bridging

Structural Insulated Panels (SIPs) are uniquely suited to addressing thermal bridging. Unlike traditional framing methods, SIPs provide an uninterrupted insulating layer, significantly minimizing heat transfer paths. Each panel consists of a solid insulating foam core sandwiched between two structural facings, typically oriented strand board (OSB).

Advantages of SIPs for Reducing Thermal Bridging

Formance SIPs offer numerous benefits for achieving H1 compliance and superior energy efficiency:

-

Continuous insulation: The absence of conventional timber framing dramatically reduces thermal bridging.

-

Enhanced airtightness: Reduced air leakage further boosts the insulation effectiveness.

-

Simplified H1 compliance: SIPs inherently align with the requirements of updated thermal performance standards, simplifying calculations and compliance.

-

Structural strength and ease of construction: Pre-fabricated panels expedite construction, reduce site waste, and ensure consistent insulation performance.

Proven Real-World Performance

Buildings constructed with Formance SIPs consistently achieve high thermal performance standards, deliver significant energy cost savings, and offer greater occupant comfort compared to conventional construction methods. SIPs are becoming the preferred choice for forward-thinking designers and engineers seeking an efficient, robust, and compliant building solution.

Explore SIPs for Your Next Project

Discover how Formance SIPs can streamline your H1 compliance process and enhance your project's thermal performance. Connect with our team today to learn more and get started.

Post your comment

Comments

No one has commented on this page yet.

RSS feed for comments on this page | RSS feed for all comments